FAPESP BIOENERGY PROGRAM - BIOEN

FAPESP BIOENERGY PROGRAM - BIOEN

The BIOEN Program aims to integrate comprehensive research on sugarcane and other plants that can be used as biofuel sources, thus assuring Brazil’s position among the leaders in the area of Bioenergy. Research includes from biomass production and processing to biofuel production and its impacts.

BIOEN has a solid core for supporting academic exploratory research related to these topics. It is expected that these exploratory activities will generate new knowledge and form scientists and professionals essential for advancing industry capacity in ethanol related technologies.

On top of this, the FAPESP Program for Research on Bioenergy establishes partnerships with industry for cooperative R&D activities between industrial laboratories and academic laboratories at universities and research institutes, which are to be co-funded by FAPESP and industry.

For these collaborations the details for each theme are specified according to the interest of the private partners and to FAPESP commitment to fostering research in the State of São Paulo. Other research agencies from federal and other state governments were invited to participate in the BIOEN Program: the Ministry for Science and Technology and Fapemig declared its interest and other agencies are studying their commitment.

The program is built with five divisions:

![]()

BIOMASS

![]()

BIOREFINERIES

![]()

BIOFUELS

![]()

END USE

![]()

SUSTAINABILITY & IMPACTS

Improvement of Biomass (Agronomy, Breeding, Biotechnology)

Identify new paths to genetically manipulate the energy metabolism of cultivated plants

Creating new biofuel alternatives

- Uncover metabolic networks related to the production of carbohydrates and sucrose through the use of “omics” technologies

- Conduct research on the molecular processes of photosynthesis

- Integrate the results in a single platform and develop bioinformatic tools to assess the information

- Discovery of genes associated with agronomic characteristics of interest

- Development of new sugar cane cultivars

- Signaling, regulation of gene expression and regulatory networks

- Genetic transformation of sugarcane and other grasses

- Molecular markers, statistical-genetics, mapping and breeding

- Sequencing, physical, genetic and molecular mapping of genomes

- Understand cell wall structure, architecture and biological function

- Discover new cellulolytic fungi species capable of degrading biomass

- Refine field practices for enhancing crop production including soil management, fertilization and precision agriculture

- Improve control of weed, pests, and diseases though chemical or biological control, resistant varieties and field practices

- Conduct research on the molecular processes of photosynthesis

Contribute with knowledge and technologies for Sugarcane Improvement

Enable a Systems Biology approach for Biofuel Crops

The goal of the Biomass Research Division is to carry out basic research on sugar cane and other biofuel plants and to create an interface between different disciplines in order to allow a systemic approach to sugar cane biology. The activities include research on organisms with lignocellulolytic activity with a potential use in cellulosic ethanol production. The challenge is to establish a new model of research and development in the area of bioenergy that will have an effective impact on the improvement of cultivars of interest. The research projects associated with biomass should address the main problems of plant biology, trying to elucidate the relation among genome, metabolism, physiological and adaptive responses to the environment. The purpose is to identify new paths to genetically manipulate the energy metabolism of cultivated plants, creating new biofuel alternatives.

The Biomass Division will also contribute to the instruction and training of qualified personnel to work in the area of Bioenergy. Groups and research areas that can contribute to the development of the program objectives will be identified through calls for research proposals.

The Biomass Research Division is led by research groups located in Institutions of the state of São Paulo. They have a longstanding experience in sugarcane genomics most of them originating from the FAPESP SUCEST Program created in 2000 to study sugarcane genomics. The BIOMASS group has a portfolio of more than 200 scientific publications in the field, five patents on genes and promoters and thirty-four sugarcane cultivars registered. There are thirty graduate students in the main research group which is associated with twenty national and seventeen international collaborating research groups, encompassing sixty researchers.

The Biomass Research Division will establish an integrated research network based on advanced science and innovative strategies that will support breeding programs in the development of new cultivars, the production of transgenic sugar cane plants, the identification and implementation of new feedstock alternatives, studies of the cell wall and enzymes to degrade it, thus contributing to consolidate Brazil’s leadership in Bioenergy.

GENOMICS, GENETICS, PHYSIOLOGY AND BREEDING

The Biomass Division will establish an integrated research and innovation network in sugar cane genomics, plant, insect and microorganism biochemistry, biotechnology and cultivar improvement. The group will train and graduate qualified researchers in Bioenergy to support breeding programs in Brazil and to obtain the intellectual property that will allow freedom to operate in the area.

Investigators will develop research on sequencing of genomes, identification of molecular markers and genes associated with agronomic characteristics of interest, production and evaluation of transgenic sugar cane, breeding and characterization of new cultivars, basic research on biology, genetics, biochemistry, plant physiology, regulatory networks of sugar cane and other model plants that may contribute to the development of research on bioenergy or that have biofuel potential. Research is also being conduct on fungi, metagenomics, insects and hydrolytic enzymes with a potential for bioefuel production.

The Division’s projects will be led by researchers located at Universidade de São Paulo, Universidade Federal de São Carlos and Universidade Estadual de Campinas.The instruction and training of qualified personnel is being improved with postgraduate programs including the international postgraduate course from USP (PGI), which consists of a tripartite partnership of USP, Ohio-State University and Rutgers University. Additionally, the Biomass Division has partnerships established with groups from USA (University of Georgia, University of Illinois Urbana-Champagne, Michigan State University) and France (CIRAD, CNRG and INRA) on genome sequencing; with France (CIRAD, CNRG and INRA) on genotyping; with USA (Purdue University), France (Research Center on Plant Macromolecules) and UK (Cambridge University) on studies of the structure of cell walls in plants; with USA (Ohio-State University), France (URGV, INRA and CNRS) and Germany (University of Potsdam) on genetics and gene expression regulation; with USA (Ohio-State University and Rutgers University) on photosynthesis; with USA (Rutgers University) on herbivory; with Australia (University of Western Austrália, University of Queensland) on ecophysiology; and with Mexico (Institut of Ecology) on functional anatomy.

General Objectives

The Biomass Research Group aims to integrate comprehensive research on sugarcane and other plants that can be used as biofuel sources, thus assuring Brazil’s position among the leaders in the area of Bioenergy. The challenge will be to guarantee innovative research in the areas of genomics, genetics, molecular biology, biochemistry, physiology, agronomy, and bioinformatics, with emphasis on studies that address the following themes:

- Genome sequencing

- Comparative, structural and evolutionary genomics of grasses

- Development of new sugar cane cultivars

- Biochemical, physiological and agronomic evaluation of cultivars

- Discovery of genes associated with agronomic characteristics of interest

- Analysis of transcriptome, proteome and metabolome

- Signaling, regulation of gene expression and regulatory networks

- Genetic transformation of sugar cane and other grasses

- Molecular markers

- Physical, genetic and molecular mapping of genomes

- Metabolic networks of the production of carbohydrates and sucrose

- Function and structure of cell walls and hydrolases in the production of cellulosic ethanol

- New fungi isolates, metagenomics for novel enzyme identification

- Bioinformatics

- Impact of climate changes and productivity

- Environmental impact of GM sugar cane and biosafety

- Intellectual property and technology transfer

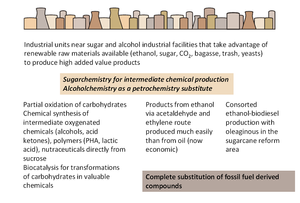

Bio-refinery consists of industrial units near sugar and alcohol industrial facilities that take advantage of renewable raw materials available (ethanol, sugar, CO2, bagasse, trash, yeasts among others) to produce high added value products. Bio-refineries benefit, also, from energy available from co-generation, as well as of the systems of residues reuse in the sugarcane farming. Bio-refinery technological opportunities include chemical derivates from sucrose (sugarchemistry); petrochemicals from ethanol and several other promising organic compounds like biodiesel, nutraceuticals and more.

GREEN CHEMISTRY

Sugarchemistry

Sugarchemistry is a promising route for the intermediate chemical production. Biochemical carbohydrates partial oxidation processes, together with the chemical synthesis for the production of intermediate oxygenated chemicals, such as alcohols and multi-functional organic acid ketones, are examples of this route that directly uses present sucrose in the sugarcane, without passing necessarily by the production of ethanol.

Biosynthetic processes like fermentation and enzyme catalyzed transformations of carbohydrates in valuable chemicals are clean routes.

Ethanol as a substitute in petrochemistry

With the knowledge acquired during the last century on the use of ethanol as raw material to obtain products normally produced from the oil substance allows the visualization of a very promising scenario for the use of the sugarcane biomass. It is worth to mention that the interruption in Brazil of alcohol-chemical processes probably occurred due to the relative high price of the products obtained through ethanol in comparison with the petrochemical via. The present scenario is different and the natural trend is the oil prices to reach higher values making economically viable other alternatives.

The advances in the reaction and separation engineering allowed the development of alternative process even more efficient that together with lower environmental impact make the use of bio-ethanol a very attractive via competing with petrochemical process even for unrealistic lower oil price.

The molecular structure of ethanol, an oxygenate product, suggests its use in more rational form as a raw material, instead of as only fuel, exactly because the production of intermediate oxygenates is difficult from the oil

There is a long list of products that can be obtained from ethanol with the following basic options: acetaldehyde route and ethylene route. The acetaldehyde can be gotten commercially by two processes: dehydrogenization and oxidation, both catalytic ones. In the case of ethylene production some processes can be identified such as the isothermal with fluidized bed reactor and the process in fixed bed reactor.

Other bio-products

The production of biodiesel is considered today, in Brazil, as one of the promising forms economically to make possible the production of a substitute of the diesel derived from the oil. The consortium ethanol-biodiesel production would be advantageous for the production of biodiesel in the agricultural aspect, for the production of the oleaginous (e.g. peanuts) in the sugarcane reform area. It could be interesting, from the industrial point of view, the use of ethanol produced for the transesterification of the vegetal oil (besides, off course, the use of the energy and available facilities). Biodiesel also could share commercialization logistic and be locally employed in sugarcane transportation and harvesting. Cake generated could be used to animal feeding.

Other examples of bio-products include:

- Derivatives of yeasts for humans and animal feeding (chelates and yeasts extract, besides high added values as specific amino acids);

- Microbial bio-degradable polymers (poly-3-hydroxybutiric acid, lactic acid, polilactic acid) for packing and medical use, produced from sucrose or from the derivatives of hydrolysis of bagasse and trash;

- Nutraceutical products, obtained by enzymatic route from sucrose presenting several advantages for the human health;

- Enzymes used in wide scale in the substitution of conventional processes of organic synthesis;

- Wax from sugarcane;

- Composites from cellulose.

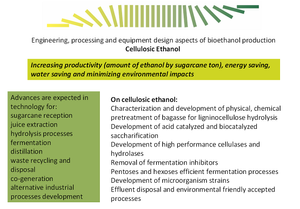

The Division of Biofuel Industrial Technologies focus mostly on the engineering, processing and equipment design aspects of bioethanol production.

Concerning ethanol industrial processes, the main challenges are related to increasing productivity (amount of ethanol by sugarcane ton), energy saving, water saving and minimizing environment impacts of the process as a whole. Several advances are expected in specific technological topics of sugarcane reception; juice extraction; hydrolysis processes; fermentation; distillation and waste recycling and disposal and co-generation. Alternative industrial processes could be also studied and developed.

Research on cellulosic ethanol and hydrolysis is one of the main goals of the Division. Lignin cellulose fiber and hemicelluloses sugarcane can be employed to produce fermentable sugars by hydrolysis, leading to an increase in ethanol production. The hydrolysis technology agenda includes topics as: pretreatments, enzymatic hydrolysis systems and processes, equipments, product separation, waste management, and others.

Hydrolyzed lignin, once successfully separated, can be burned to improve energy balance of the new process.

Commercial development of hydrolysis technologies is directly related to the success of the energy-sugarcane new paradigm. Enzymatic hydrolysis technologies promise best results from a medium and long run perspective. Hydrolysis through the acid route is presently the only feasible technology, and can also become a relevant pretreatment for enzymatic methods. Thus, research in both hydrolysis technologies, acid and enzymatic, is necessary and has a strategic nature.

It is well known that Brazil in general and the sugar and ethanol segment in particular have the best conditions for introducing commercial production of ethanol from cellulosic materials, considering that there is a large and active fuel ethanol program and bagasse is probably the most adequate lignocellulosic resource for hydrolysis.

Bagasse has the lowest price compared to other sources since it is already available at the production site and it does not need practically any prior treatment for processing. Bagasse cost is two to three times less expensive as compared to the price of biomass cultures for lignocellulosic materials in developed countries (switch grass for instance). Sugar and ethanol production generates an excess of bagasse and, if required, the available quantity can still be increased. Agricultural trashes are discarded today at the crop site but, it can be forecast as a novel resource for hydrolytic conversion by direct use or by substitution of bagasse as the fuel used by the sugar sector.

A model for introduction of hydrolysis in Brazil is strengthened due to the integration of sugar mills and distilleries. Those will provide their infrastructure for energy production, maintenance and administrative support, effluent treatment, ethanol storage and transporting. The ethanol market for local consumption and export is well established and all the network for transporting, local and export exists.

The use of lignin-cellulose biomass remaining after juice extraction will be able to raise the ethanol yield per hectare, diminishing the pressure for new areas for sugar crops.

FROM FIELD TO FUEL

The state of the art in Brazil is advanced compared to developed countries. Research conducted in Brazil by the private and public sectors brought an important contribution in terms of:

- Equipment and process design;

- Bagasse high pressure feeding technology and requirements bagasse must fulfill;

- Corrosion abrasion and material engineering;

- Lignin-cellulose material pretreatment.

- By-products formation and removal.

- Hexoses fermentation and integration of hydrolysis to sugar cane processing to ethanol, sugar and power;

- Process and energy consumption optimization.

Research lines in the BIOEN Division of Ethanol Industrial Technologies should now address:

Processing

- The use of bagasse and trash from cane processing, including the characterization and development of procedures for physical pretreatment of this raw material;

- Development of physical and chemical methods of pretreatment of raw material with the aim of disengaging the strong crystalline not attackable of lignin cellulose;

- Development of both acid catalyzed and biocatalyzed processes for saccharification;

- Development of high performance cellulases;

- Hydrolysis liquor treatment purifying in order to remove fermentation inhibitors;

- Pentoses and hexoses efficient fermentation processes, including the development of microorganism strains;

- Energy optimization of hydrolysis processes;

- Effluent disposal and environmental friendly accepted processes

The work to be done does not stop at scientific level, basic and process engineering as well as feasibility studies must be done in order to arrive to a commercial process.

Fermentation processes convert sugar raw material to ethanol. Ideally, it must be fast, efficient, flexible, and with low costs in terms of initial investments, maintenance, control, inputs and work.

Brazilian ethanol fermentation process must and can be improved in terms of yield, integration, micro organisms’ population and by-products control, final ethanol concentration, batch time and equipment design and maintenance.

There are several ways to improve fermentation process yield, including the use of high convertible carbon sugarcane varieties and incremental gains from:

- Reducing waste volume due increasing of ethanol content and/or waste recycle into the process;

- Reducing use or substitution of sulfuric acid;

- Reducing use or substitution of antibiotics;

- Reducing use or substitution of nitrogen and potassium;

- Reducing centrifugation costs from cellular recycling;

- Standardization of analytical procedures.

Additionally, due the dual nature of sugar/ethanol facilities, it is required high flexibility and resilience to easily shifting between ethanol or sugar production, and to deal with different sugarcane composition or maturation.

Microbiological studies about yeast ecology and population dynamics are perhaps one of essential themes to improve fermentation. Sugarcane juice fermented by yeasts with high alcoholic tolerance will increase its alcoholic content and therefore minimize steam consumption in the distillation and residues produced.

It is also important to develop yeasts with high thermal tolerance given that control of temperature becomes more expensive as temperature of cooling water increases, due the necessity of significantly amounts of energy to water pumping around fermentation tanks.

Ecology of the alcoholic fermentation process must be controlled, avoiding the development of contaminant bacteria that today cause productivity reduction and increasing costs with biocides and antibiotics. Flocculation problems in fermentation reactors, caused from undesirable yeasts or bacteria in proper ambient conditions.

Succession patterns of yeast ecology during fermentation cycle need to be better understood. This is essential to improve the composition and genetic quality of fermentation starters.

Finally, it is important to expend efforts in research of new process technologies. Some have been recently proposed, as the vacuum extractive fermentation, which provides a better productivity – tree fold higher – and lower steam consumption and residues production at distillation. The whole cost reduction with this system is estimated to be as high as 10%.

The mainly research goal in distillation consists of reducing steam consumption by introduction of multiple stage distillation processes. In the new energy sugarcane paradigm it would facilitate energy balance optimization of the industrial facilities.

Also the diffusion of molecular sieves and evaluation of vacuum distillation, absorption and pervaporation processes, as forms to extract anhydrous ethanol, should be considered. These technologies could substitute petrochemical products and reduce steam consumption.

Technological alternatives for treatment and use of distilling residues (vinasse), as for example, biodigestion and concentration, should be re-analyzed under the light of the new paradigm. Leaves blanket on field could change nutritional requirements.

Vinasse, so far has been applied as fertilizing, however research is still necessary in following topics: technologies of concentration, strategies of applications, measurement of environmental impacts and evaluation of impacts of biodigested vinasse effluent versus in natura vinasse. Other possibilities include vinasse combustion and protein production. It is important to point out that development of adequate solutions to each producing region becomes necessary, according to its local characteristics.

Other by-products of industrial operations, like filter cake, fusel oil and boiler leached ashes could be also subject of study, aiming recycling and environmental benefits.

Finally, it is necessary to reduce the water use for processing. CTC (at Piracicaba-SP) has developed several approaches to reducing industrial water consumption. Water use can be reduced of current 3m3/t to less than 1m3/t, producing less effluent and reducing costs, facing the governmental trend to enforce taxes for rivers water use.

Regarding thermodynamic cycle of generation and use of energy, the sector is beginning to change from using old 22 bar boilers to use 40 and up to 60 bar units. This change is motivated by energy saving considerations, involving the modification of procedures and systems that allow for more efficient electricity generation. A more relevant technological improvement, gasification technology, will also make energy generation more efficient, however it still needs to be developed and demonstrated.

An equally important task is to comply with the obligation of sugarcane harvesting without burning, which will imply is the collection of trash and its subsequent burning in boilers.

Two environment related topics are energy overall optimization of industry and controlling of burning emissions from industry facilities.

Thermo-chemical processes called BTL ("biomass to liquids") include pyrolysis and gasification technologies to be developed and compared with usual biochemical routes.

Pyrolysis is the chemical decomposition of organic materials by heating in the absence of oxygen or any other reagents, except possibly steam. The pyrolysis (or devolatilization) process occurs as the carbonaceous particle heats up. Volatiles are released and char is produced, resulting in up to 70% weight loss for coal. The process is dependent on the properties of the carbonaceous material and determines the structure and composition of the char, which will then undergo gasification reactions.

The gasification process occurs as the char reacts with carbon dioxide and steam to produce carbon monoxide and hydrogen. The resulting gas is called synthesis gas and may be more efficiently converted to energy such as electricity than would be possible by direct combustion of the biomass, as the biomass is first combusted in a boiler and the heat is used to produce steam to drive a steam turbine. Synthesis gas could be converted into liquid fuels (ethanol, 1-butanol or others) when passing in catalytic stream beds (Fischer-Tropsch process).

Other alternative is the biodigestion of the entire crop, that has potential in generating liquid fuels at lower costs to the ones of the oil.

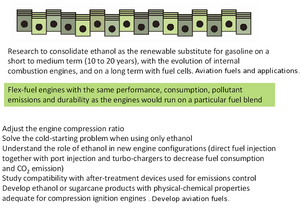

Ethanol, as a renewable source of energy, has been applied, almost exclusively, as a fuel for internal combustion engines to power vehicles.

For this application, it has to be attractive to the global automotive industry and to be competitive against other conventional and renewable fuels. Although, presently, it looks like ethanol has gained the status of global renewable fuel for spark ignition engines, there are several strong competitors to fulfill one of the global aims of the automotive industry, which is to reduce CO2 emission. Just to mention a few strategies, one can point out: the use of hybrid-electric vehicles powered by highly efficient diesel engines or direct injection gasoline engines; the application of second generation renewable fuels such as dimethyl ether or isobutanol; and the use of electric vehicles powered by batteries or fuel cells.

The past Brazilian experience with ethanol has shown that it is very difficult to break the century old development model that has been in place in the automotive industry on a global scale: to demand tighter specifications for gasoline and diesel while optimizing, respectively, spark and compression ignition engines and vehicles for those specifications. Only by using the customers demand for freedom of choice, each time they fill up their tanks, was it possible to launch the flex-fuel vehicles and to revitalize Proalcool.

To maintain the leading position of ethanol as the renewable alternative fuel to gasoline, one will have to keep it compatible with one of the principal technology pushers in power-train development, which is the compliance with future emission legislation. It is worth mentioning that the effort is directed mainly to gasoline, which represents more than 96% of all the fuel consumed by spark ignition engines in the world.

BIOFUEL ENGINES

The research challenges to consolidate ethanol as the renewable substitute for gasoline are presented in two different time scales and technology bases. The first one, on a short to medium term (10 to 20 years), relates to the evolution of internal combustion engines. The other, on a long term, deals with fuel cells, Aviation fuels and applications.

The introduction of flex-fuel vehicles broke the paradigm of one specialized engine for one strictly specified fuel, as the vehicle has to be optimized for any ethanol and gasoline blends, thereby making the development issue a lot more complex. Only through an intensive use of on-board electronics has it been possible to tackle that problem and approach the development of “optimum” flex-fuel engines.

An “optimum” flex-fuel engine has to show the same performance, consumption, pollutant emissions and durability as the hypothetical engines that would have been optimized for each particular fuel blend on which the flex-fuel engine can run.

Flex-fuel engines still represent a trade-off between using C gasoline (gasoline with a 20-25% anhydrous ethanol addition) and using hydrous ethanol. The engine compression ratio is different than the optimum ratio for a gasoline engine and the optimum ratio for a hydrous ethanol one. In addition, before flex-fuel engines can start on cold days when using ethanol, the gasoline stored in an auxiliary reservoir needs to be injected.

The short term technological challenges, demanding innovation, are how to adjust the actual engine compression ratio, perhaps by changing the closing angle of intake valves or using turbo-charging, and how to solve the cold-starting problem when using only ethanol.

The technological evolution of spark ignition engines will, probably, include direct fuel injection together with port injection and turbo-chargers, in order to decrease fuel consumption and CO2 emission. The challenge here is to understand the role ethanol can play in this new engine configuration, and to study its compatibility with the after-treatment devices that will be used for emissions control.

Plenty of research is being carried out at universities, research institutions and automotive industries on the homogeneous-charge-compression-ignition (HCCI) process that, when kept under control, promises to combine high thermal efficiency with low NOx emission. The single substance characteristics of ethanol can imply some application advantages under this process.

The ever increasing price of fuel is reinforcing the advantages Diesel-cycle engines have over Otto-cycle ones. To develop ethanol or sugarcane products with physical-chemical properties adequate for compression ignition engines is another important medium term technological challenge and Develop aviation fuels and applications.

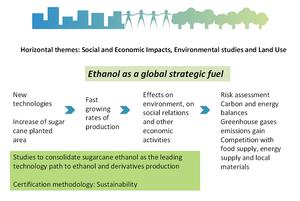

Horizontal themes: Social and Economic Impacts, Environmental studies, and Land Use

Brazil has a concrete chance for leadership in biofuel production in the next decades. However, one needs to better understand local and global market structure changes, and the conditionings behind rates and patterns of bioenergy diffusion. Particularly, the institutional set of incentives and rules adopted (or not adopted) as industrial public policy in Brazil deserves attention.

The ethanol expansion in Brazil will combine productive gains based on new technologies and increase of sugar cane planted area. Fast growing rates could generate negative impacts on environment, on social relations and other economic activities. It is important to analyze risks and to propose specific methods or policies to avoid these impacts.

Finally, as far as ethanol became a global strategic fuel and a widespread alternative to climate change challenges, topics like carbon and energy balances and greenhouse gases emissions gain special relevance.

SUSTAINABILITY ACROSS THE PRODUCTION CHAIN

Carbon and energy balances

Studies on carbon and energy balances are important to consolidate sugarcane ethanol as the leading technology path to ethanol producing and to obtain supplementary earns from international carbon credits market. Main research topics on this theme are:

- Analysis of carbon cycle in bioethanol production (sequestration, fixation, emissions);

- Energy balance and integration with other energy sources;

- Measuring methods and certification processes to carbon credits;

- Comparative studies (other energy sources, other bioethanol sources).

Social and economic impacts

Successful research will bring a production cost reduction of ethanol. Significant externalities benefiting the agricultural and industrial production are expected to generate positive impacts in the regional economy. The creation of new companies, following the concept of Biorefinery and the growing of existing companies also should bring important economic impacts.

On the social side, it is expected that an increase in competitiveness as the production grows, will cretae more jobs (the sale of a ethanol vehicle generates 22 times more jobs than that a vehicle to the gasoline) . An alteration in the profile of the jobs is to be expected, with important social consequences, due to the reduction of the manual harvest, the increase of the mechanized operations and the use of by-products, mainly of the trash.

Studies about the social and economic impacts of the agricultural and industrial production should cover:

- Number and quality of jobs created and displaced;

- Human resources needs;

- Human health benefits and hazards (on field and urban centers);

- Cultural changes;

- Net income impacts;

- Land concentration and market structure;

- Biorefinary opportunities and viability;

- Displacement effects and crowding out;

- Spillovers and spin offs;

Environmental assessment

From the environmental point of view, a sensible improvement of the sustainable indicators are expected: valorization of by-products, reduction of water consumption in the processes, reduction or elimination of cane burnings, reduction of the global emissions, more intensive use of the biological control, reduction of the fossil fertilizers needs, reduction of the requirements of herbicides, biocides, antibiotics and sulfuric acid. All these technologies represent competitive gains associate with environmental gains.

It is also expected that environment improvement due to decrease of cane field burnings and better sustainability indicators will generate a better rural environment for the population located nearby the cultivation and processing areas.

Relevant research topics include:

- Incentive policies to adoption of environmental efficient technology;

- Soil and water resources contamination and salinization (measuring, control, mitigation);

- Technology evaluation and assessment;

- Environmental monitoring of cultivated areas and industrial sites;

- Odor control;

- Forest recovering methods (river banks, high slope areas, eroded areas);

- Carbon sequestration measures in recovering forests;

Sustainability

The growing importance of the use of biomass in the world – particularly in Brazil in the form of ethanol from sugar cane – increased concerns over the sustainability of such use.

In 2005 the Dutch Parliament established a Commission with the mandate of proposing biomass sustainability criteria. The Commission produced a Report in July 2006 which covers most of the critical points. Several other activities along the same lines are being conducted, mainly in Europe and might lead the European Union to adopt non-tariff barriers to biomass products (particularly biofuels from tropical countries). It is thus of the upmost importance to assure that the explosive growth of ethanol from sugar cane production in Brazil follows reasonable sustainability criteria which will not hinder its expansion.

The first “criterium”, that is already accepted widely is that the production of biomass (or biofuel) should have an energy balance favorable i.e. the ratio of the energy output in the form of fuel to the energy inputs of fossil fuels be greater than one so the greenhouse gas (GHG) balance is positive. Ethanol from sugar cane in Brazil has a very favorable energy balance. (8:1)

Other criteria considered so far are rather general and have not led yet to a single sustainability index but they should consider:

- Competition with food supply, energy supply and local materials

- Biodiversity

- Wealth

- Welfare (labor conditions, human rights and social conditions of local populations)

The Dutch Commission recommends that none of the present conditions on the use of soil should decrease or decline due to the production of biofuels.

In addition to that, strict environment criteria should be established for:

- Waste management

- Use of agro-chemicals

- Prevention of soil erosion and nutrient depletion

- Preservation of quality and quantity of surface and ground water

- Airborne emissions

- Use of genetically modified organism (GMOs).

Under present conditions ethanol from sugarcane production in Brazil complies with regulations established by the Government, particularly in the State of São Paulo but additional research is needed in some areas.

Environment and Sustainability: fields in which additional research is needed

a. Airborne emissions

Ethanol use in Brazil has led to considerable air quality improvements in urban centers; on the other hand the sugar cane burning in the field causes problems by dispersing particulate matter and other pollutants. The main positive effects of ethanol use (whether pure or as an additive to gasoline) in urban centers are: elimination of lead compounds from gasoline; reduction of carbon monoxide emissions; elimination of sulphur and particulate matter; and less toxic and photochemically reactive emissions of organic compounds. Ethanol contains no sulfur, olefins, benzene, or other aromatics all of which are components of gasoline that can affect air quality and threaten human health. With ethanol fuel combustion, emissions of the toxic air pollutants acetaldehyde, and peroxyacetyl nitrate (PAN) increase relative to straight gasoline. Most of the emissions are released as acetaldehyde, a less-reactive and less-toxic pollutant than formaldehyde. None of the pollutant is present in the fuel; they are created as byproducts of incomplete combustion.

b. Water

Conversion of cane to ethanol requires large amounts of water. The total use of water is calculated to be 21 m3/t cane, 1997, of which 87% is used in four processes: cane washing, condenser/multijet in evaporation and vacuum, fermentation cooling and alcohol condenser cooling. Environmental problems relating to water quality, which result from irrigation (water run-off, with nutrients and pesticides, erosion) and industrial use, are seldom found in São Paulo. In this respect, EMBRAPA rates sugar cane as Level 1 (no impact on water quality).

The stillage, or vinasse, which is a black liquid, formed during the distillation process however is an important wastewater flow. Vinasse is highly organic loaded and produced in large volumes and has a pH of 4-5. Vinasse is hot and therefore requires cooling.

A number of studies in respect to leaching and possibilities of underground water contamination with vinasse indicate that there are generally no damaging impacts for applications of less than 300 m3/ha.

As inorganic pollutants in ethanol production it can be cited: agrochemicals such as herbicides, insecticides, fungicides, maturators, adhesive spreading agents and defoliants. The Brazilian legislation, including rules and regulations from production to use and disposal of materials, cover all important aspects.

Pesticide consumption in sugar cane crops is lower than in citric, corn, coffee and soybean crops; the use of insecticides is low, and that of fungicides is virtually non-existent.

c) Use of genetically modified organism (GMOS)

Sugar cane diseases are fought against through the selection of disease-resistant varieties in major genetic improvement programs. This procedure has been sufficient to address the occurrences in large proportions, such as the mosaic virus (1920), the sugar cane smut and rust (1980’s), and through replacement of varieties. Genetic modifications (at field test stage) have produced plants resistant to herbicides, smut, the mosaic virus and the sugar cane beetle.

d) Land Use

In the State of São Paulo, which responds for 61% of the Brazilian cane production, there is still significant space for an expansion of the production capacity through the use of areas already occupied by pasture. In 2004, the areas in the State used for pastures reached 10.18 million hectares, whereas the area used for cane harvesting for industrial purposes totaled only 3.42 million hectares.

e) Soil

Sugarcane is not a particularly demanding crop in terms of soil, adapting reasonably to soils of average fertility and high porosity / permeability - sandier soils. Obviously, more fertile soils implicate in higher productivity levels, and/or smaller demand for fertilizers and corrective products. However, these are areas of larger land cost. The most critical element is precipitation, because cane crops demand a minimum of 900mm of well distributed rainfalls per year. As the distribution of rains is not uniform, a good precipitation average that guarantees minimum requirements would be 1400 mm/year. Areas that demand financial resources for irrigation purposes are more problematic, in view of the considerable initial investments and the cost of the energy used in irrigation.

Sugar cane crops have been expanding in areas having poorer soils (especially “highly anthropized cerrados”, mostly extensive pastures). They contribute to the recovery of those soils by adding organic matter and chemical-organic fertilizers, which also contribute to improve the physicochemical conditions of the soil, thereby incorporating them into Brazil’s agricultural area. The sugar cane culture in Brazil is renowned for its relatively small soil erosion loss (compared to soybean and corn, for example).

f) Biodiversity

The biodiversity’s impact from the production can be summarized as follows: the direct impact of cane production on biodiversity is limited, because cane takes place so far mainly in areas of pastures and/or food crop. These areas are far from the biomes (see a map) like Amazon Rain Forest, Cerrado, Atlantic Forest, Caatinga, Campos Sulinos and Pantanal or riparian forests. The amount of harvesting area in the Centre-South region increased from 2.8 Mha in 1993 to 4.2 Mha in 2003 and is expected to increase by some 50% to 2010.

The agricultural land use practices’ impacts for conventional crops can be dramatic, affecting everything from biodiversity to the global climate. The biggest threat posed by expanding the amount of land under cultivation for energy or any other use is the irreversible conversion of virgin ecosystems. Deforestation, for example, causes the annihilation of species and their habitats, and the loss of ecosystem functions. Studies reveal that wide-scale destruction of forests can affect the hydrologic cycle and the climate, reducing regional precipitation and increasing temperatures.

Institutional bottlenecks and competitive determinants

The sustainable growing of ethanol production in Brazil must consider solutions to several institutional bottlenecks and efforts to conjugate comparative and competitive advantages.

Main research topics include:

- Infrastructure and logistic planning;

- Regulatory and incentive needs;

- Electric power supplying contracts;

- Metrology and normalization;

- Quality, traceability and characterization of main sugarcane products;

- Domestic and foreign markets dynamics, and related politics, of main sugarcane products;

- Emerging technical and non-technical barriers to international ethanol trade;

- Economic viability determinants of optimum scale and state of art industrial facilities, financing strategies;

- Technology foresight;

- Strategies for intellectual property protection;

- Public research and development (R&D) infrastructure needs and coordination;

- Human resources development.